杭氧压缩机赢得了良好的声誉——高可靠性、经久耐用、满足所有工艺流程用的各种工况需求。

消化、吸收国外先进技术:进行设计、选材、制造和检验,并符合美国API 618 标准要求。

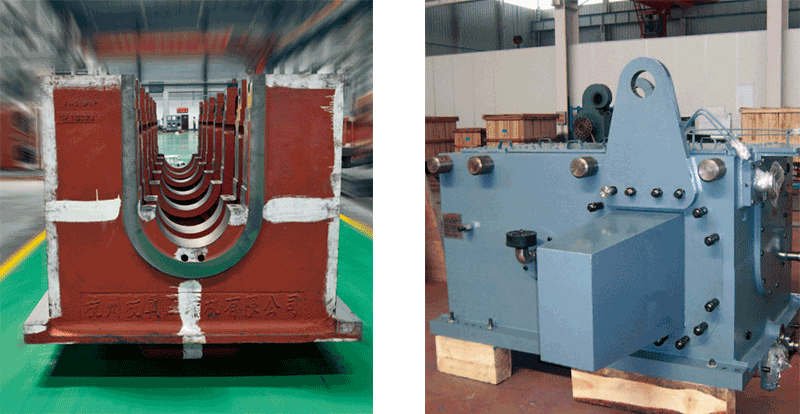

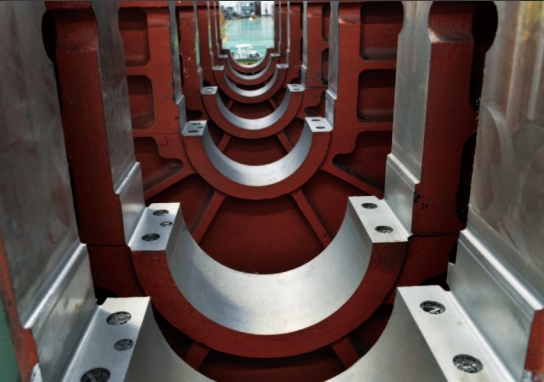

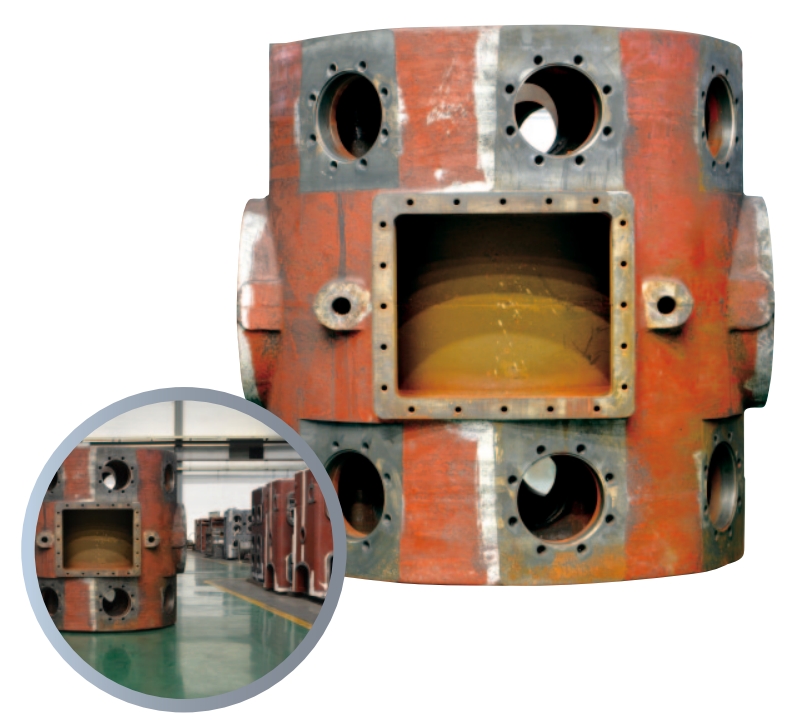

| 机身 Frame | ||

机身由细晶粒铸铁整体浇铸,采用加强筋结构。保证轴承座用精确镗削加工而成。 机身带有轻顶盖和侧盖,方便对轴承和零件的保养维修,还可以配置压力释放装置。 The frame is integrally cast with fine grained iron and adopts the structure of strengthening rib, and its bearing seat is precisely bored. The frame is provided with light top cover and side cover to facilitate maintenance of the bearing and the parts, and it may be fitted with pressure release unit. |  | |

驱动端 Drive end

曲轴的驱动端有一个大的与本体整体锻造的法兰盘,可牢固地用螺栓固定在飞轮上,与电机轴法兰或联轴器相接。高刚度的法兰连接设计可以承

受通常压缩机扭矩的变化。

The drive end of crankshaft is provided with a big bulk-integrally forged flange, which may be surely fixed onto the flywheel with bolts, and is connected

with motor shaft flange or coupler. The highrigidity flange connection design may withstand the usual variation of compressor torque.

| 轴瓦 Bearing shell | |

| 坚实、精确加工的曲柄销瓦和主轴瓦表面镀有极薄的巴氏合金涂层,确保最佳的磨合性能和长时间使用。按API 614 设计的循环润滑油系统对轴瓦实现压力润滑。曲拐之间主轴 瓦和驱动端的轴瓦提供了最稳定的支撑,确保曲轴挠度、内应力和轴瓦载荷最小。 高精度的主轴承安装在每个曲拐的两边,使得支撑良好,工作寿命长。 The surface of the durable and fine-machined shell crankpin bearings and the shell main bearings is coated with an extreme-thin Babbitt metal to ensure the optimal conformability and long service time. The circulation lubrication oil system designed as per API 614 realizes the forced lubrication of the bearing shell. The shell main bearings between the crankshaft throws and the bearing shell at the drive end are provided with the most stable supports to minimize the crankshaft deflection, the inner stress, and the load of the bearing shell. The high-precision main bearings are fixed at both sides of each crankshaft throw to ensure good support and long service life. |

|

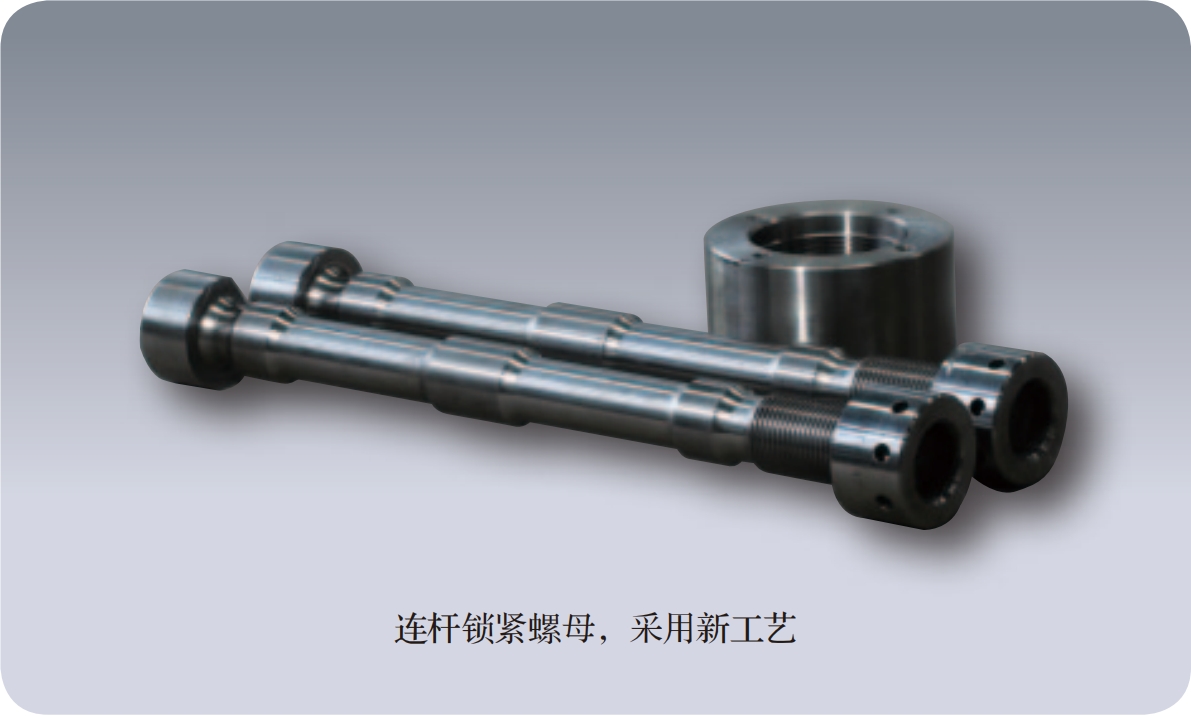

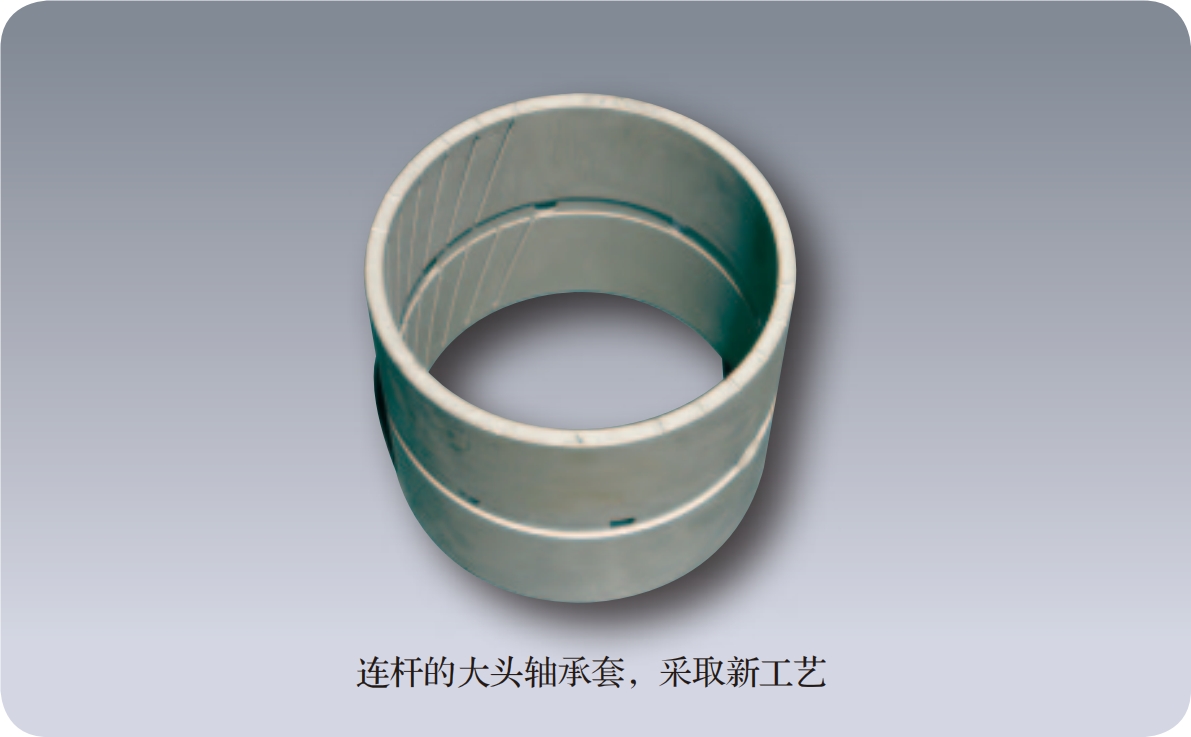

连杆 Connecting rod

压缩机连杆采用高强度模锻钢制造,深孔加工可润滑十字头销。十字头销衬套(连杆小头瓦)更换非常方便。

The compressor connecting rod is made of highstrength die forge steel, and the deep-hole machining may lubricate the cross-head pin. The crosshead pin bush (bush at the smaller end of the connecting rod) is easily replaceable.

|  |  |

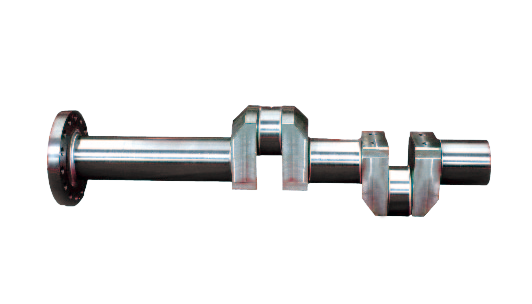

| 曲轴 Crankshaft | |

使用高强度合金钢锻件,经过消除内应力和热处理。全部轴颈和曲拐经过精磨和抛光工序达到粗糙度标准,磨合良好。每个曲拐两边都有轴瓦,使得挠度减小到最小。 It is made of high-strength alloy steel forging and is subjected to elimination of inner stress and heat treatment. All journals and crankshaft throws are finely ground and polished to meet the roughness standard and ensure the good conformability. Each side of the crankshaft throw is provided with bearing shell to minimize the deflection. |  |

活塞杆 Piston rod

螺纹用精轧制成,活塞杆经电感应硬化处理,材质具有高疲劳极限强度和长磨损寿命能承担恶劣的工况。标准 活塞杆材料是38CrMoAlA 或42CrMoA,

根据需要可以采用其它材料。可以表面进行处理以增加硬度。

The threads are finely rolled, and the piston rod is subjected to electric-induction hardening treatment. The material has high fatigue ultimate strength

and long wear life, and withstands the worse case. The piston rod is made of standard material 38CrMoAlA, 42CrMoA, or other materials else, and its

surface is treated to increase.

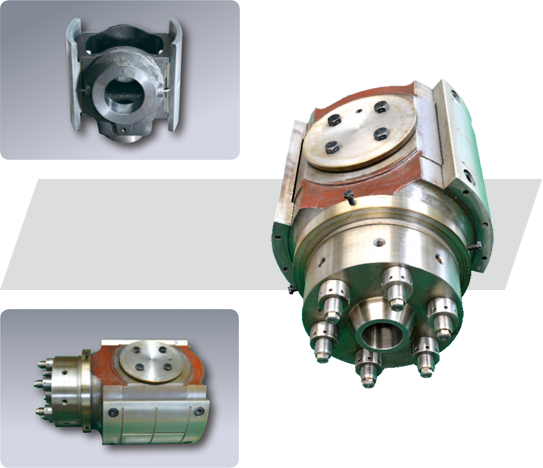

| 十字头 Crosshead | |

|

在大范围内的速度和负荷内提供安全保证。装有上下滑履。不拆卸即可调整活塞杆的中心位置。平衡重可以容易地加上或卸下,以得到初始惯性力。一种特殊的十字头“超级螺母”不需大的扳手或用液压上紧装置。 It ensures safety within large range of speed and load. It is fitted with the upper and the lower slide shoe, and the center position of piston rod may be adjusted without removal of them. The balance weight may be easily loaded or unloaded to obtain the initial inertia force. A special crosshead "Supernut" needs no big wrench nor hydraulic tightening unit. |

| 活塞和活塞环 Crosshead | |

有油润滑和无油润滑活塞环和支承环使用的材料为PTFE(填充聚四氟乙烯)或其它复合材料。这些设计避免活塞和缸套直接接触,工作寿命得以延长,特别是在润滑有可能被中断一段时间的情况下。 PTFE (filled polytetrafluoroethylene) or other compositematerials are used in the oil-lubricated and oil-free pistonring and wear band, and this design may prevent thepiston and cylinder liner from direct contact, which mayincrease the service life, especially in the case where thelubrication may be interrupted for a while. |  |

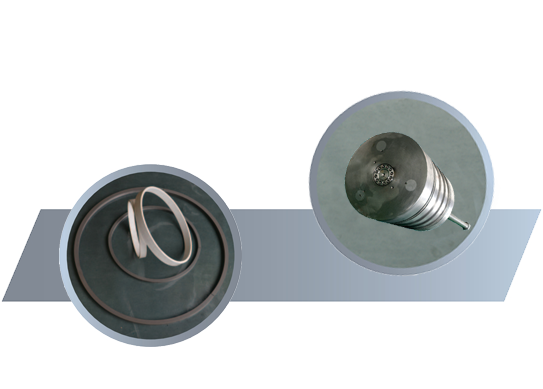

为了适应最新对环境要求的工况,控制填料处的气体泄漏。采用特殊的缓冲密封环和不同组合的自动补偿环。两个单独的锲形环把受阻尼气体从两边密封住。达

到最严格的防泄要求。根据不同用途和API 618 标准,可以在填料上设置润滑油道、冷却水道和通气孔。

In order to adapt the case for the latest environmental requirement and control the gas leakage from the packing, the special pulsation damper seal ring and

different combinations of automatic compensation rings are used. Two independent wedged rings from two sides seal the damped gas to meet the strictest

anti-leakage requirement. As per the usages and API 618 standard, the packing is provided with the lubricationoil passage, cooling water passage and vent.

网状阀片PEEK 材料特点 Features of material of PEEK plate (plate valve)

◇ 重量轻:PEEK 阀片为金属阀片的六分之一,减少惯性力和冲击力及磨损,使用寿命增加。 | ◇ Low weight: The weight of PEEK valve plate is merely 1/6 of that of metallic valve plate and it decreases inertia force, impact force, and wearing out, and prolongs the service life. |   |

| ◇ 耐腐蚀:几乎所有种类的工艺气体,包括100%H2S 和低于3%的氯气或HCl 或100%HCO 等各种酸性气体,承受气体中液体和渣质。 | ◇ Corrosion resistance: It suits for almost all process gases, including acidic gasses such as 100% H2S, chlorine of concentration below 3%, HCl, or 100% HCO, and withstands the liquid and residual herein. | |

| ◇ 大升程:是金属阀片的2 倍升程可减少气体流经气阀的阻力,并提高使用寿命。 | ◇ High lift: Its lift is twice of that of metallic valve plate, and thus it can decrease the resistance of the gas passing through the valve and increase the service life. |

卸荷器的特征 Characteristics of the unloader

| ◇ 导杆对卸荷器阀对中,确保正向定位准确,使泄漏量最小。 | ◇ The guide rod is aligned with the unloading valve to ensure correct positioning and minimize the leakage. |  |

| ◇ 套筒型卸荷器阀,减少承受压差的面积,在通风工作气压下密封性能有显著提高。 | ◇ The sleeve type unloading valve decreases the area suffered from the differential pressure and remarkably improves the sealing capacity in ventilation working pressure. | |

| ◇ 阶梯式杆设计,确保运行安全可靠。 | ◇ The step type rod design ensures safe and reliable operation. |

气缸 Cylinder

压缩机随着气量、压力、温度和气体类型的不同而不同,几十年压缩机运用的经验使得发展了一整套的高效可靠的气缸系列。适用于各种场合。 气缸的材质有:铸铁、球铁、铸钢、组合式碳钢或不锈钢、锻钢等。适用于有油润滑及无油润滑的各种工况。 The compressors will be different depending on the gas volume, pressure, temperature, and The cylinders are made of cast iron, ductile cast iron, cast steel, composite carbon steel, stainless steel, or forged steel, and are suitable for various oil-lubricated and oil-free cases. |  |

| 我们使用的接筒可以用于所有的气体压缩工艺,有油润滑气缸、无油润滑气缸、腐蚀性、可燃或易爆、有毒等会污染曲轴箱机油的气体。大多数被压缩的气体是危险的、有腐蚀性、有毒或容易燃烧,因此产品的接筒都采用气密设计,根据需要排放或充氮。 有API“D”型双室接筒和长的API“B”型标准单接筒,所有的接筒体上均设有金属盖板密封的窗口,以便填料保养。 由于接筒承担了往复运动活塞杆的最大载荷,为了加强接筒的强度,接筒采用球铁铸造,并采轧制螺纹的螺栓稳妥地把接筒固定在机身和气缸之间。 Our distance piece is suitable for any gas compression process, which involves with the oil-lubricated cylinder or oil-free cylinder, and corrosive, inflammable, explosive and toxic gases which would contaminate the machine oil in the crankshaftcase. Most to-compress gases are dangerous, corrosive, toxic or inflammable, and thus the distance piece of the product adopts the air-tight design, and as per the requirement the gas is discharged or nitrogen is filled. |

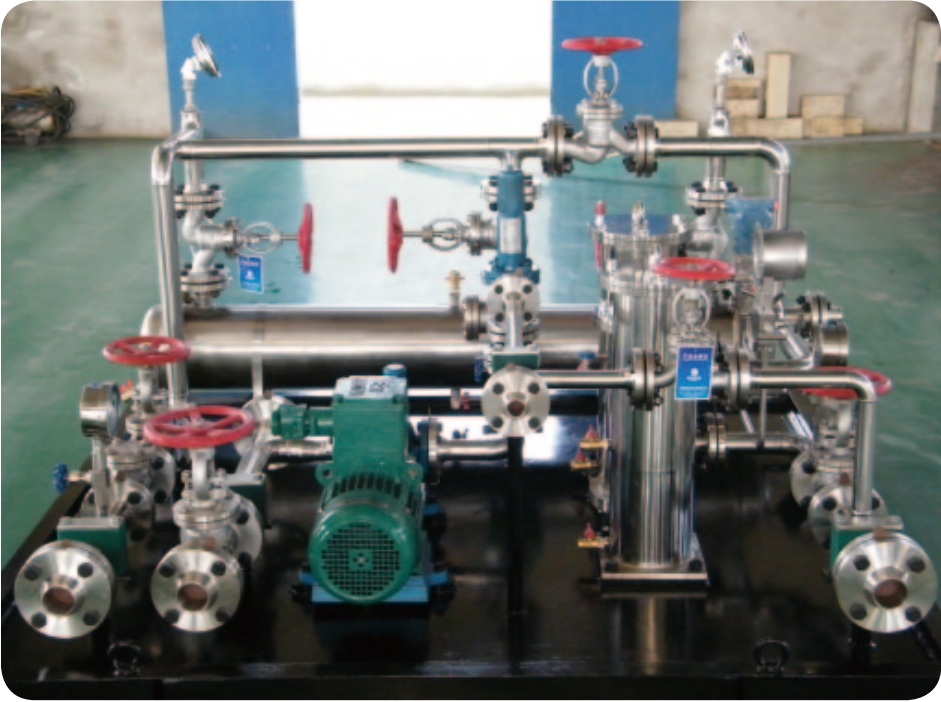

水站 Water station

API 618 循环式冷却系统可以根据用户要求设计制造,满足不同情况的要求。图示为一个典型的标准设计制造的水站系统。 API 618 circulation cooling system may be designed and manufactured as per client's requirement to satisfy the specific case. Here, a typical standard designed and manufactured water station system is shown. |

|

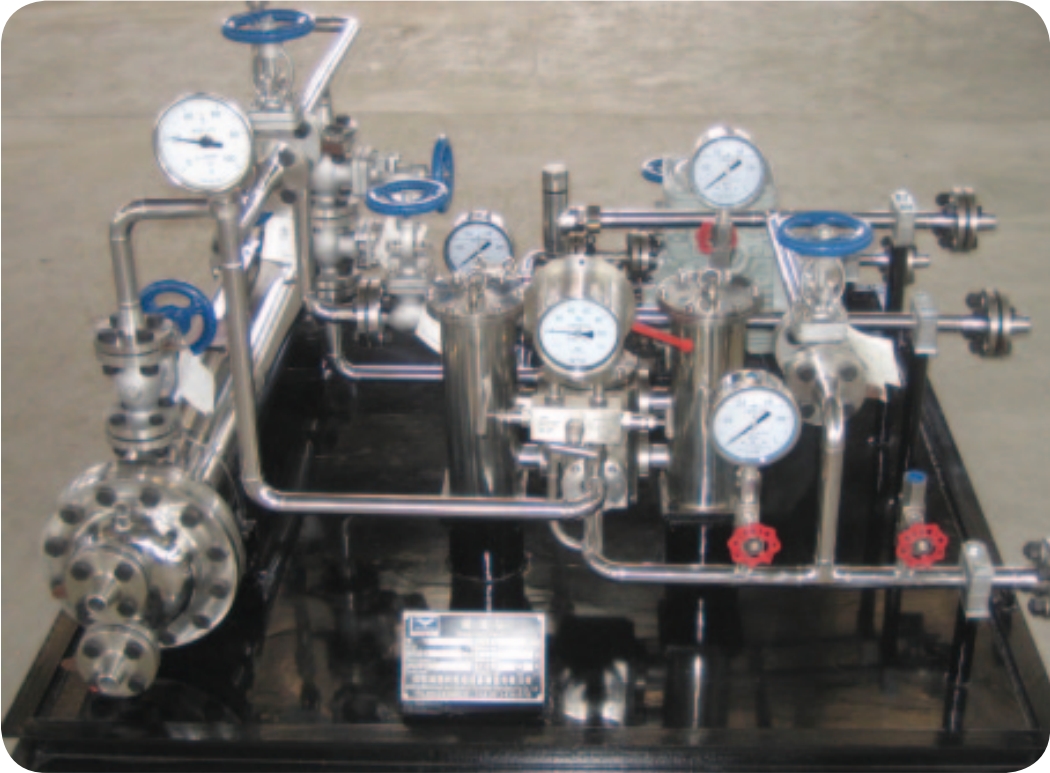

API 614 循环润滑油系统,全部在工厂测试,能满足使用要求。它包括筒式过滤器、轴头泵和辅助油泵、底座和管式冷却器、油压表、开关、温度仪表、控制阀等。

API 614 circulation lubricating oil system is entirely tested in the factory, and it meets the use requirements, and includes barrel type filter, shaft head pump, auxiliary oil pump, base, tube type cooler, oil pressure gauge, switch, temperature instruments and control valve.

|  |  |

声学脉动振动分析对气管站作完整的模拟,包括气缸流道、气阀、缓冲器。气管路上的冷却器、分离器、阀门和管支架。在各个关键的位置设置模拟测试采集

有关数据,并重点对根源—气缸和减振元件缓冲器进行详细全面的分析。

Acoustic fluctuation and vibration analysis completely simulates the gas pipe station, including the cylinder passage, gas valve, pulsation damper, the

cooler, separator and valve on the gas pipeline, and pipe holder.The key locations are provided with simulators to test and collect related data and overall in details

analyze the vibration source: cylinder and vibration absorbing element-pulsation damper.

公司提供的整套往复式压缩机组严格按照API 和ISO 标准进行设计和制造,公司将为您提供最优质的产品和服务。

Our complete set of reciprocating compressors are designed and manufactured in strict accordance with API and ISO standards and we will provide our best

products and services.

当尺寸允许时,采用整机装箱,简化安装,省时。 如果机组的尺寸超过了装箱的限制,在工厂内装配和测试后,按组件安排运输,提供专用的封盖,保障运输,简化现场的再组装。 一切从节省用户时间和费用的观念出发,采用合理化装箱运输方式,使得现场焊接、气缸对中和其它装配时间减至最少。 If the dimensions are allowable, the entire compressor will be packed to simple the installation and save the time.If the dimensions of the unit exceed the restriction on packing, after assembly and test in the factory, the components are transported and provided with special covers to ensure the transportation, and simple the reassembly at site. For saving client's time and expense, the rational packing and transportation mode is used to minimize the time in site welding, cylinder alignment, and other assembly. |  |

在工厂完成装配试车后,每个气缸、接筒和中体(如果是分开的)作为一个组件进行运输。

After assembly and test in factory, each cylinder, distance piece and intermediate body (if separable) will be transported as one assembly.

装有连杆的机身,用刚性的保护盖保护着。这保证了在现场组装机身和气缸更简易、更快捷和更精确。

The connecting-built frame is protected with a rigid protective cover, which will make the site assembly of both the frame and the cylinder much simple, fast and precise.

整机装箱待运。

Packing the complete compressor and getting ready for shipping.

实施全过程项目管理,确保准时发运。

Management of all times of the entire process willensure on time delivery.