Hangyang Compressors enjoy high prestige:high reliability and durability, and satisfying demands on cases of all technical processes.

Its design, material-selection, manufacture and inspection are made through digestion and absorbing of the advanced technologies of abroad, and it conforms to API 618.

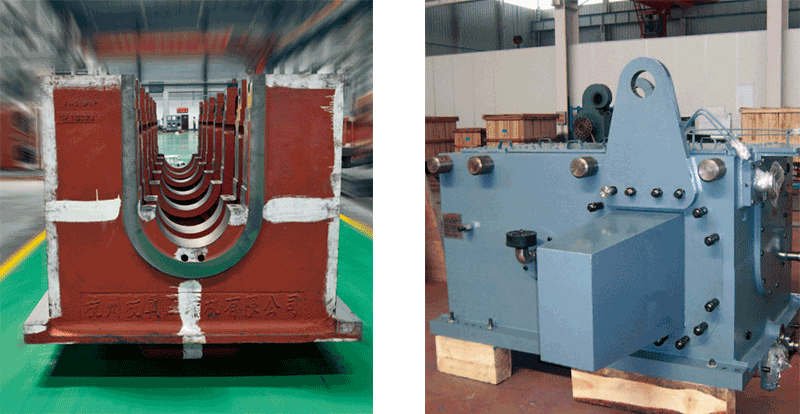

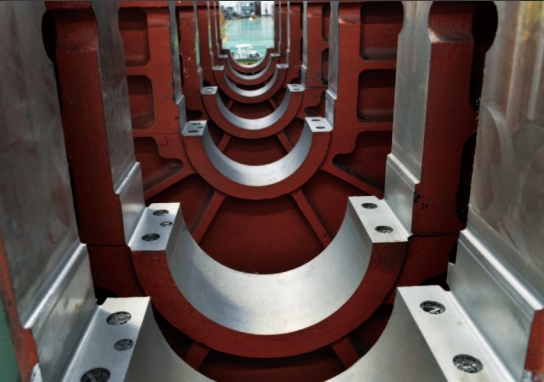

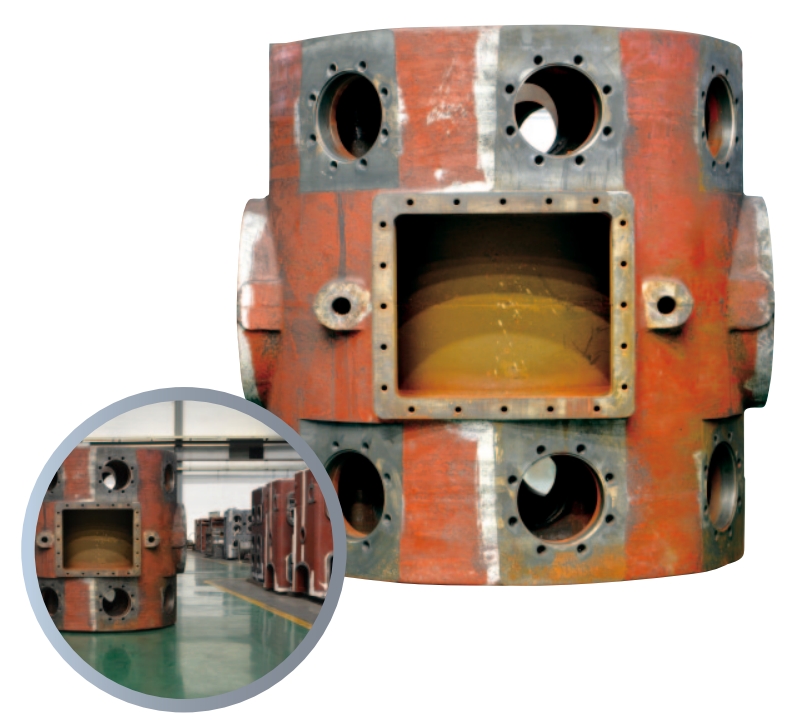

| Frame | ||

The frame is integrally cast with fine grained iron and adopts the structure of strengthening rib, and its bearing seat is precisely bored. The frame is provided with light top cover and side cover to facilitate maintenance of the bearing and the parts, and it may be fitted with pressure release unit. |  | |

Drive end

The drive end of crankshaft is provided with a big bulk-integrally forged flange, which may be surely fixed onto the flywheel with bolts, and is connected

with motor shaft flange or coupler. The highrigidity flange connection design may withstand the usual variation of compressor torque.

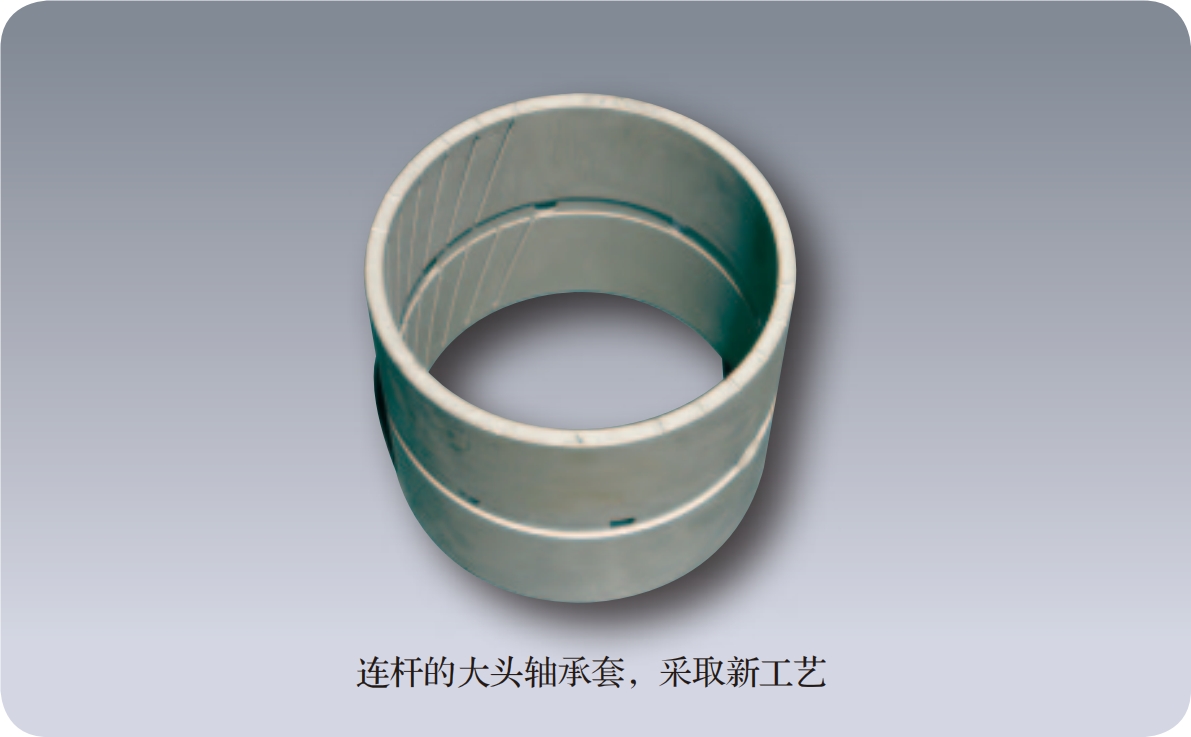

| Bearing shell | |

The surface of the durable and fine-machined shell crankpin bearings and the shell main bearings is coated with an extreme-thin Babbitt metal to ensure the optimal conformability and long service time. The circulation lubrication oil system designed as per API 614 realizes the forced lubrication of the bearing shell. The shell main bearings between the crankshaft throws and the bearing shell at the drive end are provided with the most stable supports to minimize the crankshaft deflection, the inner stress, and the load of the bearing shell. The high-precision main bearings are fixed at both sides of each crankshaft throw to ensure good support and long service life. |

|

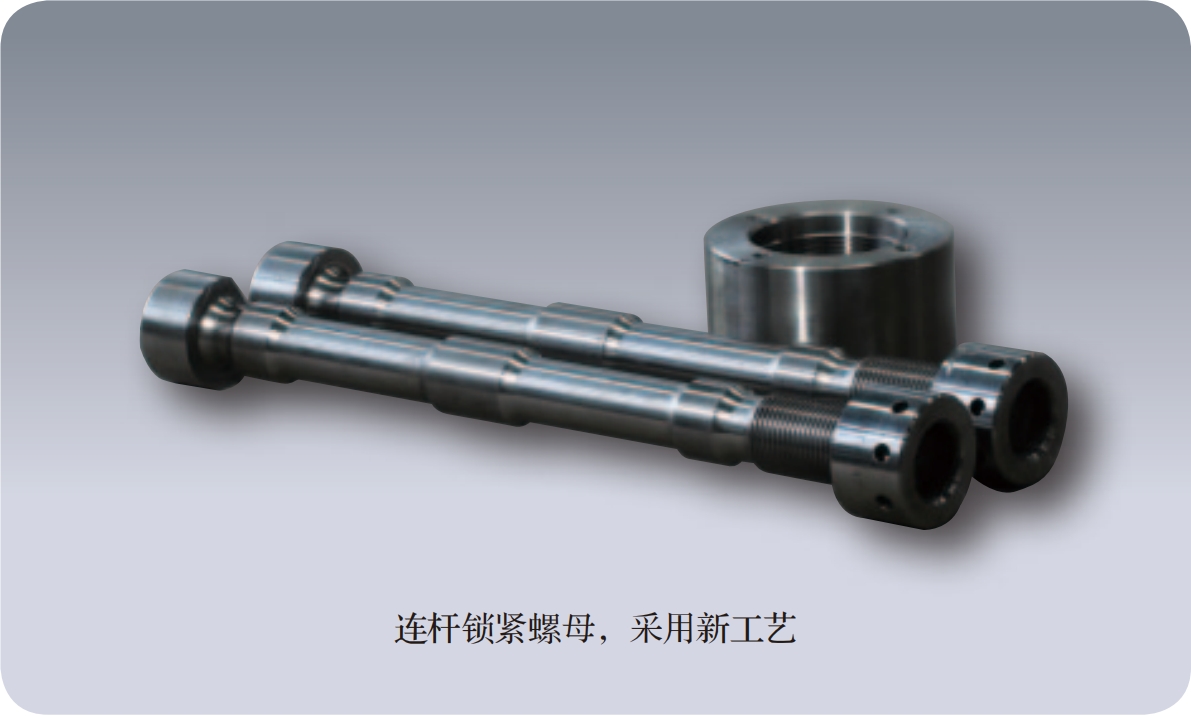

Connecting rod

The compressor connecting rod is made of highstrength die forge steel, and the deep-hole machining may lubricate the cross-head pin. The crosshead pin bush (bush at the smaller end of the connecting rod) is easily replaceable.

|  |  |

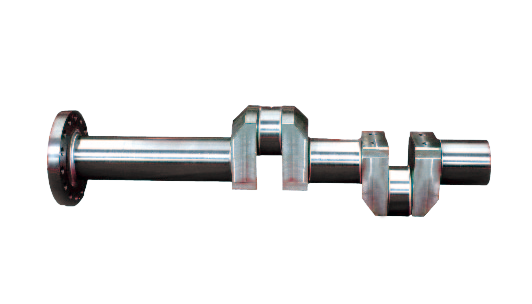

| Crankshaft | |

It is made of high-strength alloy steel forging and is subjected to elimination of inner stress and heat treatment. All journals and crankshaft throws are finely ground and polished to meet the roughness standard and ensure the good conformability. Each side of the crankshaft throw is provided with bearing shell to minimize the deflection. |  |

Piston rod

The threads are finely rolled, and the piston rod is subjected to electric-induction hardening treatment. The material has high fatigue ultimate strength

and long wear life, and withstands the worse case. The piston rod is made of standard material 38CrMoAlA, 42CrMoA, or other materials else, and its

surface is treated to increase.

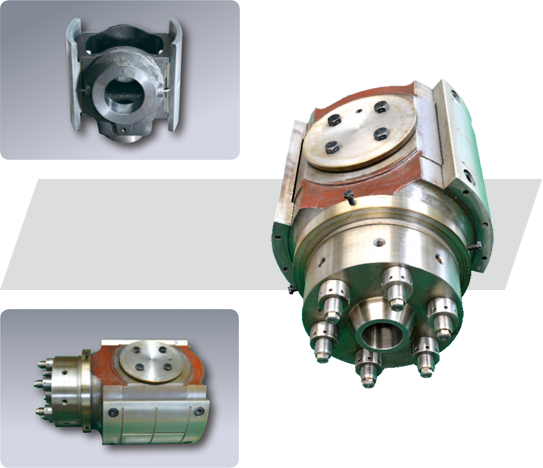

| Crosshead | |

|

It ensures safety within large range of speed and load. It is fitted with the upper and the lower slide shoe, and the center position of piston rod may be adjusted without removal of them. The balance weight may be easily loaded or unloaded to obtain the initial inertia force. A special crosshead "Supernut" needs no big wrench nor hydraulic tightening unit. |

| Crosshead | |

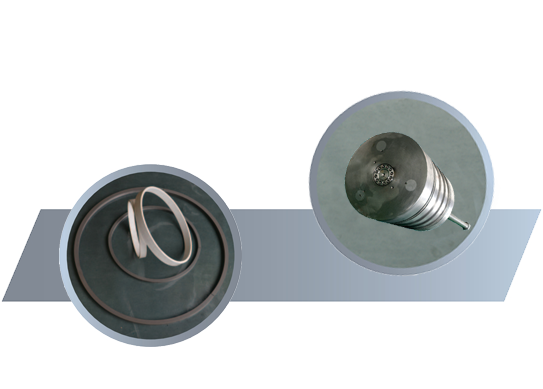

PTFE (filled polytetrafluoroethylene) or other compositematerials are used in the oil-lubricated and oil-free pistonring and wear band, and this design may prevent thepiston and cylinder liner from direct contact, which mayincrease the service life, especially in the case where thelubrication may be interrupted for a while. |  |

In order to adapt the case for the latest environmental requirement and control the gas leakage from the packing, the special pulsation damper seal ring and

different combinations of automatic compensation rings are used. Two independent wedged rings from two sides seal the damped gas to meet the strictest

anti-leakage requirement. As per the usages and API 618 standard, the packing is provided with the lubricationoil passage, cooling water passage and vent.

Features of material of PEEK plate (plate valve)

| ◇ Low weight: The weight of PEEK valve plate is merely 1/6 of that of metallic valve plate and it decreases inertia force, impact force, and wearing out, and prolongs the service life. |   |

| ◇ Corrosion resistance: It suits for almost all process gases, including acidic gasses such as 100% H2S, chlorine of concentration below 3%, HCl, or 100% HCO, and withstands the liquid and residual herein. | |

| ◇ High lift: Its lift is twice of that of metallic valve plate, and thus it can decrease the resistance of the gas passing through the valve and increase the service life. |

Characteristics of the unloader

| ◇ The guide rod is aligned with the unloading valve to ensure correct positioning and minimize the leakage. |  |

| ◇ The sleeve type unloading valve decreases the area suffered from the differential pressure and remarkably improves the sealing capacity in ventilation working pressure. | |

| ◇ The step type rod design ensures safe and reliable operation. |

Cylinder

The compressors will be different depending on the gas volume, pressure, temperature, and The cylinders are made of cast iron, ductile cast iron, cast steel, composite carbon steel, stainless steel, or forged steel, and are suitable for various oil-lubricated and oil-free cases. |  |

| Our distance piece is suitable for any gas compression process, which involves with the oil-lubricated cylinder or oil-free cylinder, and corrosive, inflammable, explosive and toxic gases which would contaminate the machine oil in the crankshaftcase. Most to-compress gases are dangerous, corrosive, toxic or inflammable, and thus the distance piece of the product adopts the air-tight design, and as per the requirement the gas is discharged or nitrogen is filled. |

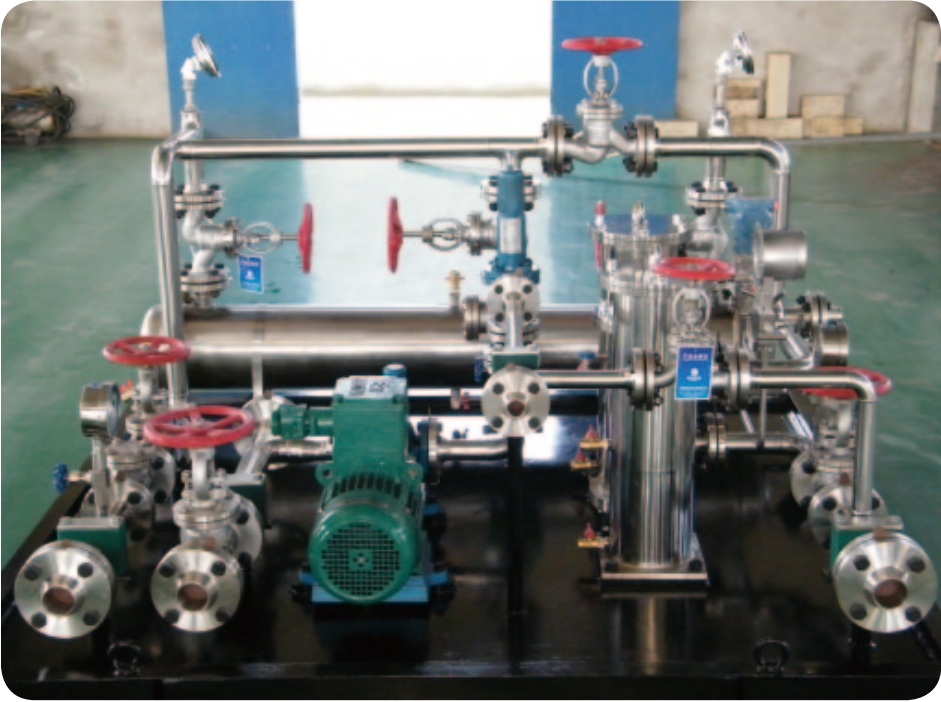

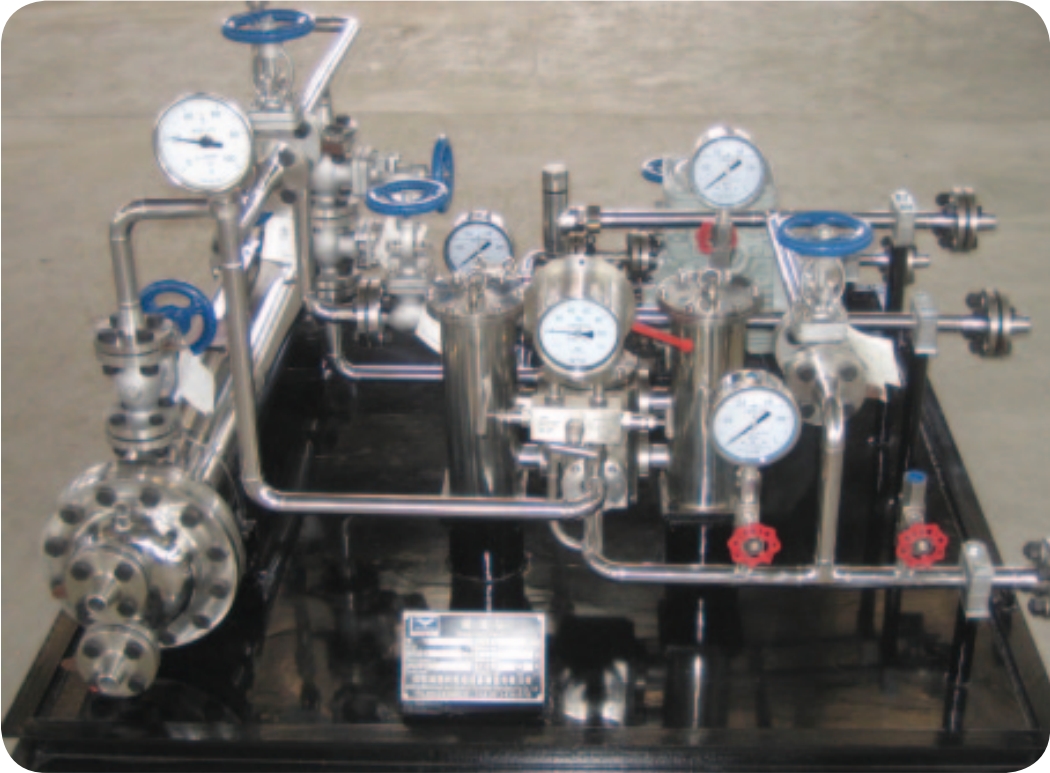

Water station

|

API 614 circulation lubricating oil system is entirely tested in the factory, and it meets the use requirements, and includes barrel type filter, shaft head pump, auxiliary oil pump, base, tube type cooler, oil pressure gauge, switch, temperature instruments and control valve.

|  |  |

Acoustic fluctuation and vibration analysis completely simulates the gas pipe station, including the cylinder passage, gas valve, pulsation damper, the

cooler, separator and valve on the gas pipeline, and pipe holder.The key locations are provided with simulators to test and collect related data and overall in details

analyze the vibration source: cylinder and vibration absorbing element-pulsation damper.

Our complete set of reciprocating compressors are designed and manufactured in strict accordance with API and ISO standards and we will provide our best

products and services.

| If the dimensions are allowable, the entire compressor will be packed to simple the installation and save the time. If the dimensions of the unit exceed the restriction on packing, after assembly and test in the factory, the components are transported and provided with special covers to ensure the transportation, and simple the reassembly at site. For saving client's time and expense, the rational packing and transportation mode is used to minimize the time in site welding, cylinder alignment, and other assembly. |  |

After assembly and test in factory, each cylinder, distance piece and intermediate body (if separable) will be transported as one assembly.

The connecting-built frame is protected with a rigid protective cover, which will make the site assembly of both the frame and the cylinder much simple, fast and precise.

Packing the complete compressor and getting ready for shipping.

Management of all times of the entire process willensure on time delivery.